A New User's Guide to Industrial Coffee Grinder Choices

A New User's Guide to Industrial Coffee Grinder Choices

Blog Article

Leading Attributes to Try To Find in an Industrial Coffee Mill

When examining an industrial coffee mill, it is crucial to determine crucial features that affect both efficiency and long life. Uniformity in work size is vital for ideal removal, while adjustable grinding speed allows for a balance between effectiveness and high quality.

Work Size Consistency

While numerous aspects can affect the quality of made coffee, grind size consistency stays paramount in accomplishing optimal extraction. The uniformity of coffee premises directly impacts the developing procedure, as unequal fragment dimensions can lead to over-extraction or under-extraction. This variance causes unbalanced tastes, where specific notes may be subduing while others are muted.

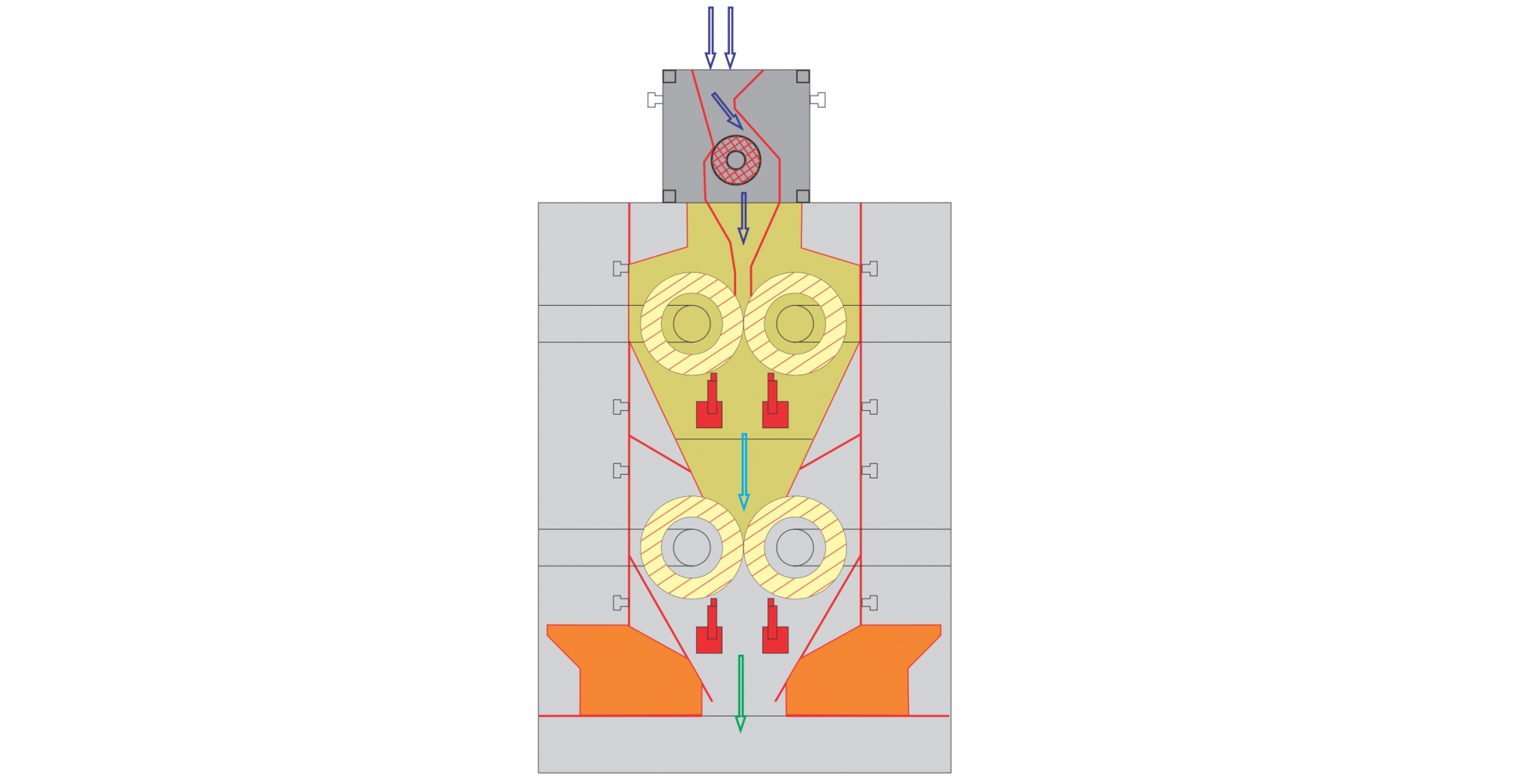

Industrial coffee grinders are created to offer a high level of accuracy, often utilizing burr grinding devices to ensure an uniform grind size. Unlike blade mills, which can produce a mix of penalty and rugged particles, burr grinders squash the beans in between 2 surface areas, enabling far better control over work dimension. This uniformity is essential across different brewing techniques, whether coffee, French press, or pour-over, as each strategy needs particular work sizes for optimum flavor extraction.

Furthermore, consistency in grind size contributes to the overall efficiency of the brewing procedure. A consistent grind enables also water flow, reducing the risk of improving and directing removal performance. In summary, buying a commercial coffee mill with a concentrate on grind dimension consistency is necessary for accomplishing premium coffee with preferable flavor accounts.

Grinding Rate

Grinding rate plays an essential function in the overall efficiency of industrial coffee grinders, straight affecting both the high quality of the grind and the performance of the operation. Industrial Coffee Grinder. Higher grinding speeds can significantly boost the throughput, making it possible to process bigger quantities of coffee beans in a shorter timespan. This is especially important for companies that count on high-volume manufacturing, such as coffee roasteries and coffee shops

Nonetheless, while rate is crucial, it is similarly important to stabilize it with the high quality of the grind. Exceedingly high grinding speeds can create warm, which might adversely influence the flavor account of the coffee by triggering the beans to shed necessary oils and scents. As a result, a mill that provides adjustable rate setups can provide optimum versatility, permitting drivers to customize the grinding process according to specific demands.

In addition, the grinding speed should correspond to make certain uniformity in the grind dimension, more adding to the total taste and brewing high quality of the coffee. In recap, evaluating grinding speed is critical for picking a commercial coffee mill that fulfills both efficiency and high quality needs.

Build Top Quality and Sturdiness

The efficiency of an industrial coffee mill is not solely determined by its grinding speed; construct quality and sturdiness are similarly essential aspects that affect lasting efficiency and dependability. A well-constructed mill will hold up against the roughness of everyday use, making it a sound investment for any type of industrial operation.

Sturdiness likewise encompasses the mill's motor and internal mechanisms. Industrial coffee grinders need to be furnished with heavy-duty motors qualified of maintaining long term procedure without overheating. Additionally, durable burrs are vital, as they directly influence the top quality of the grind and add to the general longevity of the machine.

Ease of Usage and Maintenance

Continually prioritizing simplicity of use and upkeep can dramatically boost the operational performance of an industrial coffee mill. Straightforward functions such as intuitive controls and clear labeling are crucial for decreasing downtime and making sure that drivers can swiftly adapt to the equipment. An ergonomic layout, including height-adjustable receptacles and available grinding chambers, enables comfortable operation and promotes the loading and discharging of coffee beans.

In addition, simplicity of maintenance is vital for lengthening the life-span of the grinder. Devices with this website detachable components and parts made for quick cleansing can streamline maintenance tasks, minimizing the moment spent on regular upkeep - Industrial Coffee Grinder. Try to find mills that include self-cleaning systems or call for minimal disassembly, like it as these functions can conserve beneficial labor hours

Additionally, clear maintenance timetables and documents are vital. Mills that come with extensive individual manuals laying out maintenance procedures can assist drivers abide by ideal practices, making sure regular efficiency and top quality. By buying an industrial coffee grinder that highlights ease of use and maintenance, organizations can enhance performance, lower functional prices, and maintain the high standards expected in coffee production.

Sound Level Decrease

When selecting an industrial coffee grinder, noise level decrease is a critical factor that can significantly affect the workplace. High noise levels can result in worker exhaustion, lowered focus, and possible hearing damage in time, making it crucial to pick a mill created with sound-dampening features.

Search for grinders that incorporate innovative noise-reduction modern technologies, such as sound-insulated housings and vibration-dampening mounts. These attributes aid to reduce operational sounds, developing a quieter ambience favorable to efficiency. Industrial Coffee Grinder. Furthermore, picking grinders outfitted with low-noise electric motors can even more enhance sound reduction, guaranteeing a more positive functioning atmosphere

Consider the mill's general design, too. Designs with incorporated sound-absorbing products can dramatically reduce noise discharges during grinding cycles. The placement of the mill within the work space must be tactical. Placing it on a steady, heavy surface can aid to decrease resonances that add to sound.

Inevitably, buying a coffee grinder that prioritizes sound reduction not only enhances the convenience of employees yet additionally lines up with a commitment to maintaining a effective and risk-free work setting. This interest to detail can result in boosted staff member contentment and retention.

Final Thought

In summary, selecting a commercial coffee mill demands careful consideration of a number of essential useful reference features. Grind size consistency is necessary for ideal extraction, while adjustable grinding rate assists in a balance in between throughput and top quality.

Industrial coffee mills are developed to provide a high degree of accuracy, typically utilizing burr grinding devices to guarantee a consistent work size. Unlike blade grinders, which can create a mix of penalty and rugged particles, burr mills crush the beans in between 2 surfaces, enabling for much better control over grind dimension. In recap, investing in a commercial coffee grinder with a focus on grind size uniformity is important for attaining high-grade coffee with preferable taste profiles.

Grinding speed plays a crucial duty in the general performance of commercial coffee mills, directly impacting both the high quality of the work and the efficiency of the operation. A grinder that provides adjustable speed setups can supply optimal versatility, allowing drivers to tailor the grinding procedure according to details needs.

Report this page